Carbon monoxide poisoning occurs when CO builds up in your bloodstream. When too much carbon monoxide is in the air, your body replaces the oxygen in your red blood cells with carbon monoxide. This can lead to serious tissue damage, or even death. Carbon monoxide is a colourless, odourless, tasteles...

Loading and Unloading Hazards – Truck Trailers

Loading and Unloading Hazards : Drivers can potentially be injured while loading, strapping/securing, and tarping loads. They then have the same injury potential when they reach their destination and unload their trucks. Proper loading and unloading procedures should be established by employers. All...

Permit to Work Systems

Permit to Work System (PTW) is where proposed work is identified as having a high risk, strict controls are required. The work must be carried out against previously agreed safety procedures, a ‘permit-to-work’ system. The PTW is a documented procedure that authorises certain people to c...

Vacancy for Safety Officer

Vacancy for Safety Officer – Qatar, UAE, KSA A client is looking for urgent vacancies (100) for safety officer. Pay package 2000-3000 SAR + food & accommodation. Visa & ticket will be provided by company, Can expect immediate mobilization. Any Graduate with Nebosh I...

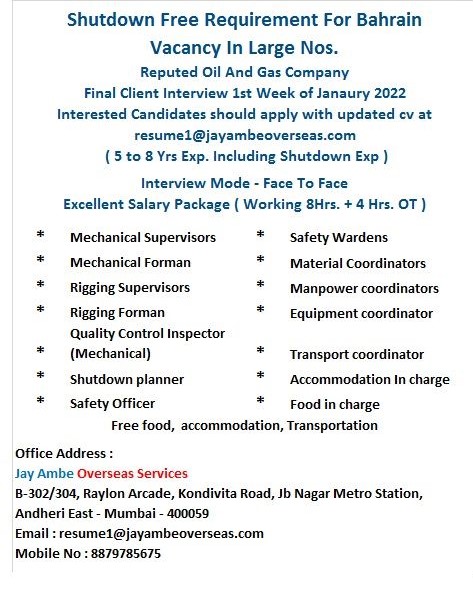

Safety Vacancy – Bahrain

Safety Vacancy abroad – As received on 18th Dec 2021 For NEBOSH/IOSH courses dial 9447609617 / 8606108000...

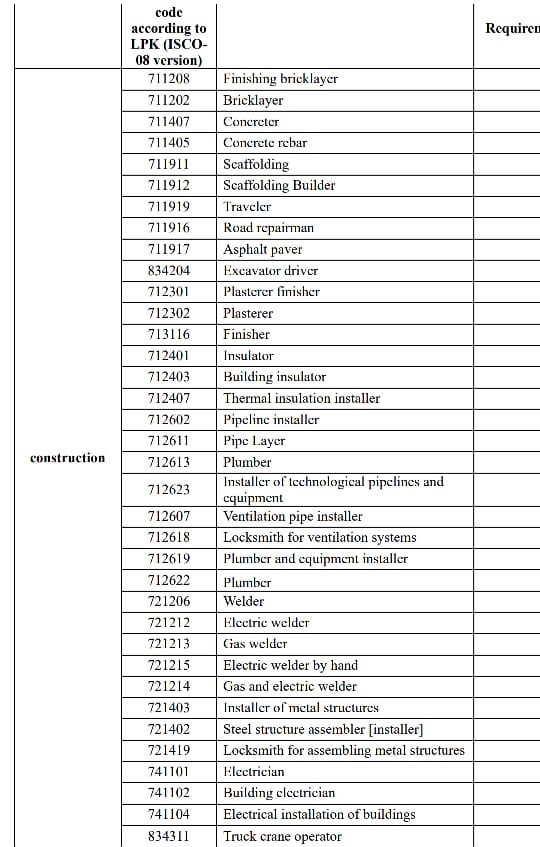

Vacany in Lithuania & Norway

Vacany in Lithuania & Norway – Bulk Recruitment – Construction Field As received on 19th November 2021 Salary skill workers 8_10 euro per hour Helpers 5 euro per hour Interested candidates can send CV to hr@asheinstitute.com...

Working at height

Working at height remains one of the biggest causes of fatalities and major injuries. Common cases include falls from ladders and through fragile surfaces. ‘Work at height’ means work in any place where, if there were no precautions in place, a person could fall a distance liable to caus...

Risk assessment and Managing risks at work

Managing risks and Risk assessment at work As an employer, you’re required by law to protect your employees, and others, from harm. Under the Management of Health and Safety at Work Regulations 1999, the minimum you must do is: Firstly, identify what could cause injury or illness in your busin...

SAFETY VACANCY ABROAD

Safety Vacancy Safety Vacancy requirement as follows Senior HSE Officer (NEBOSH required) (4) HSE Officers (NEBOSH required) Senior Mechanical Design Engineer Mechanical QA/QC Engineer Document Controller (Aconex required) Only local applicants (currently in Qatar) with valid QID who can start immed...

EHS INSPECTOR JOB in DUBAI

EHS INSPECTOR JOB Dear Delegates Happy to let you know that multiple vacancies exist as EHS Inspector in a well reputed property development company in Dubai. NEBOSH IGC holders from ASHE Institute can undergo 5 days training conducted at Kochi and then attend interviews by company officials. It is ...

OFFICE SAFETY

Office Safety Rules The company expects workers to follow its safety. These safety rules are for your safety only. Please use these safety rules on the jobsite to keep yourself and others safe. Employees must wear their seat belts when driving on company business. Report to work free from the aftere...

SAFETY OFFFICER VACANCY

Safety Officer Vacancy in Kochi As received on 3rd February 2021 QualificationB.Tech – Fire & Safety/ Diploma- Industrial Safety from Factories & Boilers approved institutions. Experience: 0-10 yrsAge: 19 – 50 Job Description: Responsible for all safety functions at the fac...

Safety Vacancy in Punjab

Safety Vacancy in Punjab, Shutdown Safety Job, Guru Nanak Refinery, 2 years Experience needed. Immediate Joining at punjab...

BSS Skill Certification

Bharath Sevak Samaj skill mission, Govt. of India Promoted certification now at ASHEI....

HSE Officer Required

HSE Officer Required in Dubai for a reputed construction company As received on 10th February 2020 Qualification needed: NEBOSH Passed, Engineering. SARS Card is must. Language proficiency: Should be fluent inEnglish & Hindi. Immediate Joining! Qualified candidates can send CV to almadarmgm@gmai...

Safety Officer Vacancy @ Saudi Arabia

Qualification: NEBOSH IGC + Diploma / Engineering Safety Officer vacancy @ KSA (Kingdom of Saudi Arabia) Experience: Two years Salary 2000 SAR. Food acc. Free. Free Recruitment. ASHEI Students Preferred Qualified & interested candidates can send CV to: placement.ashei@gmail.com...

SOLAR ECLIPSE on 26th DECEMBER 2019

SOLAR ECLIPSE What is Solar Eclipse? An eclipse occurs when the moon passes in front of the sun, blocking it out partially or completely. The eclipse results in parts of the earth being covered in the shadow of the moon. What Causes Solar and Lunar Eclipses? An&nb...

HSE Vacancy in Saudi

As received on 5th December 2019 HSE Vacancy NEBOSH IGC is considered the gold standard in Health & Safety domain which has been revamped and published by NEBOSH lately. ASHEI, proudly certified as the ‘NEBOSH’s SILVER Learning Partner in Kerala, India. ASHEI provides the necessary materials...

Are you aware of NEBOSH IGC course new Syllabus?

Do you know that NEBOSH has made significant changes to their Qualifications. New syllabus update for NEBOSH IGC released...

SAFETY ASSISTANT VACANCY @ ABUDHABI

Safety Assistant Required For Abudhabi ASHEI students only! Qualification: Iosh + 1 year diploma safety Graduation preferred, Hindi Language Must. Salary: AED 1500 + Food & Accommodation Send Whatsapp message to 8593913939 CV to placement.ashei@gmail.com...

Emergency Kit Supplies

Emergency Kit Supplies Water: one gallon per person, per day (3-day supply for evacuation, 2-week supply for home) Food: non-perishable, easy-to-prepare items (3-day supply for evacuation, 2-week supply for home). Flashlight Battery-powered or hand-crank radio Extra batteries First aid kit Medic...

Precautions to be taken for a FLOOD

Precautions to be taken for a FLOOD – Safety tips for floods We are hit again with flood second time… Although it was learned last time it is better to refresh what is expected precautions during exposure to flooded area… Tips you need to remember:- Driving in Rain – Driving Safe...

Safety Tips For Monsoon Season

Safety Tips For Monsoon Season The monsoon season is when people eagerly look towards the sky for cool, refreshing showers, which come as a relief after the scorching heat of summer. Although it rejuvenates every living organism, one should be careful about the dangers and diseased prevalent during ...

Safety Officer

Safety Officer Machinery & Systems Machinery & Systems Safety Officer In order to be skilled get qualified at Ashei and employed abroad. Present vacancies for those who have experience of… Machinery & Systems Safety Officer ISO Management Systems & associated processes Machine...

HSE MANAGER VACANCY UAE

HSE MANAGER VACANCY UAE Bio-Safety Specialist at Qatar Urgent Vacancy at Biomedical Research Center! As received on 15th October 2018. Post: Bio-Safety Specialist Location: Qatar ONLY WITH GENUINE QUALIFICATION AND EXPERIENCE NEED TO APPLY HSE MANAGER VACANCY UAE Bio-Safety Specialist Qualicat...

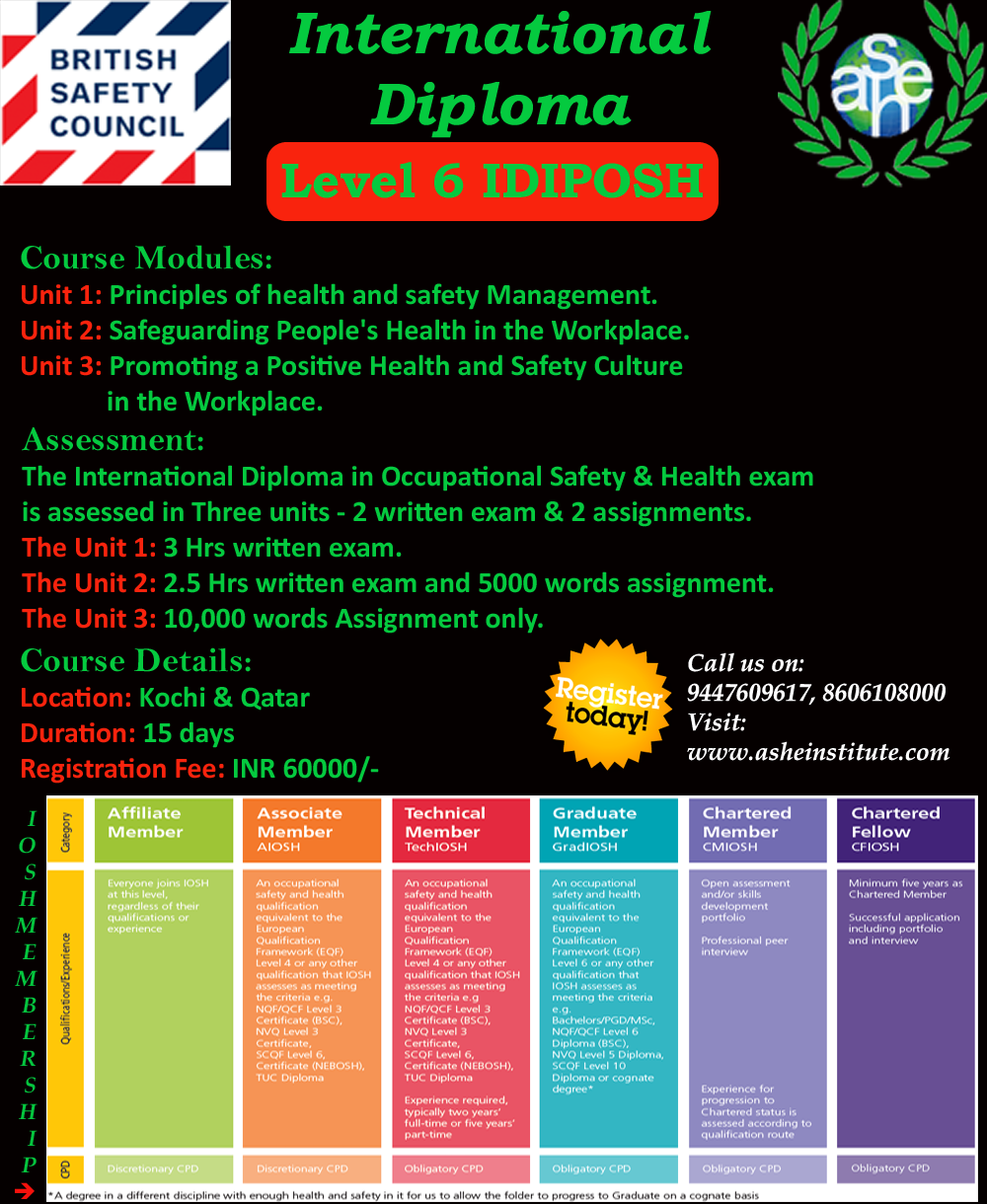

BSC Idip at Kochi Get upgraded to Grad IOSH

BSC Idip at Kochi Get upgraded to Grad IOSH BSC Idip at Kochi Get upgrade to Grad IOSH International Diploma : Course dates for BSC Idip at Kochi on April 8&9 Exam. Certainly a must for HSE professional. And those who are looking to upgrade their professional status.In addition to the course....

Coming Home after a Flood!

Coming Home after a Flood, Returning Home After Flood. Going back home after a flood can be dangerous if precautions are not been taken Coming Home after a Flood, The floodwaters are receding in Kerala as the week-long heavy rains are waning. Yet, for those planning to return home, it is advisable ...

Office safety -Ergonomics

Office safety . Safety training at kochi Sitting Wrong At Your Workplace Your Entire Life… If this is the posture you maintain at work, read below common reason for you suffer from the pain. That back pain keeps you off job whol day. Because of that it reduces your performance at work. what is t...

Safety equipment for employers

TYPES OF PERSONAL PROTECTIVE EQUIPMENT (PPE) TO GUARANTEE YOUR SAFETY As an employer, you are in charge of a safe and healthy working environment for your employees. You are familiar with the safety risks within your sector, as well as the measures you can take to counteract these risks. WHAT IS PER...

HSE MANAGER PACKAGE ASHEI KOCHI

BSC Level 6 IDIP-OSH at Kochi HSE MANAGER PACKAGE ASHEI KOCHI International Health and Safety Training From Qualified tutors at ASHEI… https://www.facebook.com/events/119608495574766/ Get yourself upgraded with ISO 45001!!!! Lead Auditor Course @ ASHEI Kochi. (Migration from OHSAS) ...

ISO 45001 Auditor course OHSMS

ISO ISO 45001 Auditor course Get yourself upgraded from OHSAS 18001 to ISO 45001. course commence on 24 May at kochi. call 8606108000 ISO 45001 Auditor Course Registration open for next batch Call 9447609617 8606108000...

British Safety Council IDIP (UK) Level 6

British Safety Council IDIP IDIP course commence from Jul 24th at ASHEI Kochi. British Safety council Examination on Aug 8&9. To enrol mail to info@asheinstitute.com or call 9447609617. in order to register call us...

IOSH MANAGING SAFELY Version 5.0 @ ASHEI KOCHI 8606108000

IOSH MANAGING SAFELY Version 5.0 @ ASHEI IOSH MANAGING SAFELY The Institution of Occupational Safety and Health (IOSH) is a British organization for health and safety professionals. The IOSH Managing Safely Certificate Course focuses on specially training the managers. And supervisors of any organ...

LIST OF INDIAN STANDARDS ON SAFETY & HEALTH

LIST OF INDIAN STANDARDS ON SAFETY & HEALTH https://www.facebook.com/notes/ashe-institute/list-of-indian-standards-on-safety-health/1454504327997502/ NEBOSH IGC @ ASHEI KOCHI TUTOR : ANILKUMAR TS MENON CMIOSH FIIRSM OCTOBER BATCH REGISTRATION ONGOING…. CLASS STARTING ON: 9 – 19TH ...

risks from electricity

risks from electricity What are the risks from electricity? Harm can be caused to any person when they are exposed to ‘live parts’ that are either touched directly or indirectly by means of some conducting object or material. Voltages over 50 volts AC or 120 volts DC are considered hazardous. El...

EMS Auditor – ISO 14001:2015 Training Course @ ASHEI Kochi 8606108000 www.asheinstitute.com

EMS Auditor – ISO 14001:2015 Training Course @ ASHEI Kochi 8606108000 www.asheinstitute.com IRCA Certified EMS Auditor / Lead Auditor – ISO 14001:2015 Training Course EMS Auditor- IRCA is the leading professional body for management system auditors and offers a globally recognized business qua...

Health And Safety Auditing In Ernakulam | Cochin

International Safety course in kochi!!! Health And Safety Auditing In Ernakulam / Cochin ISO 45001: 2018 IRCA Approved LA Training Course @ ASHEI Kochi Training By ANILKUMAR TS MENON We conduct batches every month for ISO 45001:2018 LA, EMS- ISO 14001:2015 LA, ISO 45001:2018- Migration cou...

Accident Investigation

Accident Investigation WHAT IS IT? Accident investigation is the process of determining the root causes of accidents, on-the-job injuries, property damage, and close calls in order to prevent them from occurring again. WHY IS IT IMPORTANT? Accident investigation will lead you to the real cause of wh...

Safety courses @ ASHEI KOCHI

Health and Safety Course Qualification Health and Safety at work – HSW – A perfect introduction to health and safety. This introductory qualification will help improve the safety culture in your organisation. By equipping your workforce to identify and deal with hazards at work. Hence i...

IADC Rigpass

IADC Rig Pass Course IADC HSE Rig Pass program ready for instant use! Ideal for the small & medium sized in-house contractor programs or commercial training organizations. Highlights: Pre-approved HSE Rig Pass curriculum –facilitates provider accreditation * Suitable for classroom, rig-based, ...

NEBOSH GC3 – HEALTH AND SAFETY PRACTICAL APPLICATION – UNIT : III

GC3 Guidance and information for candidates NEBOSH GC3 is the third paper to pass the nebosh IGC Qualification. First of all this document provides comprehensive guidance on the presentation and submission of the Unit GC3 practical application. Also it includes guidance on the structure and style ...

COMMAND WORDS FOR NEBOSH IGC – EXAM TIPS

Command word & Definition Command words are important to note while writing the examination. Identify – To give reference to an item, which could be its name or title. NB: normally a word or phrase will be sufficient, provided the reference is clear. Give – To provide short, fact...

Hot Weather Safety

Hot Weather Safety Hot weather safety is one of the major aspects in safety SUNLIGHT • Sunlight produces ultraviolet radiation • No ultraviolet radiation is safe SKIN CANCER • Melanoma is the deadliest form of skin cancer • Melanoma is nearly 100% curable if found early • Melanoma can spr...

VIOLENCE in WORKPLACE

What is workplace violence? VIOLENCE in WORKPLACE is violence or the threat of violence against workers. It can occur at or outside the workplace and can range from threats and verbal abuse to physical assaults and homicide, one of the leading causes of job-related deaths. However it manifests its...

SILICA DUST

Silica Silica dust, often referred to as quartz, is a very common mineral. It is found in many materials common on construction sites, including soil, sand, concrete, masonry, rock, granite, and landscaping materials. The dust created by cutting, grinding, drilling or otherwise disturbing these mate...

Safety Glasses Work

Safety Glasses Work Eye injuries are 100 percent preventable. Your eyes are very delicate, made of thin tissues that can’t take much damage. You can’t blink fast enough to prevent an injury. Significant surgeries are required when serious damage occurs. Shavings, grindings and other particles ca...

Atmospheric Testing in Confined Space

Atmospheric Testing in Confined Space Atmospheric testing is required for two distinct purposes: evaluation of the hazards of the permit space and verification that acceptable conditions exist for entry into that space. A confined space is one that is large enough to enter and perform assigned work ...

NEBOSH Health and Safety at Work Qualification

NEBOSH Health and Safety at Work Qualification Health and Safety at Work Qualification A perfect introduction to health and safety. This introductory qualification will help improve the safety culture in your organisation, by equipping your workforce to identify and deal with hazards at work helping...

WhatsApp us

WhatsApp us