Permit to Work System (PTW) is where proposed work is identified as having a high risk, strict controls are required. The work must be carried out against previously agreed safety procedures, a ‘permit-to-work’ system. The PTW is a documented procedure that authorises certain people to c...

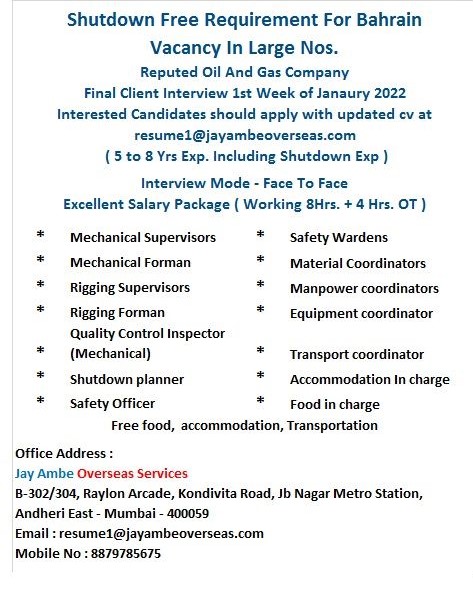

Safety Vacancy abroad – As received on 18th Dec 2021 For NEBOSH/IOSH courses dial 9447609617 / 8606108000...

EHS INSPECTOR JOB Dear Delegates Happy to let you know that multiple vacancies exist as EHS Inspector in a well reputed property development company in Dubai. NEBOSH IGC holders from ASHE Institute can undergo 5 days training conducted at Kochi and then attend interviews by company officials. It is ...

Bharath Sevak Samaj skill mission, Govt. of India Promoted certification now at ASHEI....

SOLAR ECLIPSE What is Solar Eclipse? An eclipse occurs when the moon passes in front of the sun, blocking it out partially or completely. The eclipse results in parts of the earth being covered in the shadow of the moon. What Causes Solar and Lunar Eclipses? An&nb...

As received on 5th December 2019 HSE Vacancy NEBOSH IGC is considered the gold standard in Health & Safety domain which has been revamped and published by NEBOSH lately. ASHEI, proudly certified as the ‘NEBOSH’s SILVER Learning Partner in Kerala, India. ASHEI provides the necessary materials...

Do you know that NEBOSH has made significant changes to their Qualifications. New syllabus update for NEBOSH IGC released...

Safety Assistant Required For Abudhabi ASHEI students only! Qualification: Iosh + 1 year diploma safety Graduation preferred, Hindi Language Must. Salary: AED 1500 + Food & Accommodation Send Whatsapp message to 8593913939 CV to placement.ashei@gmail.com...

Emergency Kit Supplies Water: one gallon per person, per day (3-day supply for evacuation, 2-week supply for home) Food: non-perishable, easy-to-prepare items (3-day supply for evacuation, 2-week supply for home). Flashlight Battery-powered or hand-crank radio Extra batteries First aid kit Medic...

Safety Officer Machinery & Systems Machinery & Systems Safety Officer In order to be skilled get qualified at Ashei and employed abroad. Present vacancies for those who have experience of… Machinery & Systems Safety Officer ISO Management Systems & associated processes Machine...

HSE MANAGER VACANCY UAE Bio-Safety Specialist at Qatar Urgent Vacancy at Biomedical Research Center! As received on 15th October 2018. Post: Bio-Safety Specialist Location: Qatar ONLY WITH GENUINE QUALIFICATION AND EXPERIENCE NEED TO APPLY HSE MANAGER VACANCY UAE Bio-Safety Specialist Qualicat...

IOSH MANAGING SAFELY Version 5.0 @ ASHEI IOSH MANAGING SAFELY The Institution of Occupational Safety and Health (IOSH) is a British organization for health and safety professionals. The IOSH Managing Safely Certificate Course focuses on specially training the managers. And supervisors of any organ...

LIST OF INDIAN STANDARDS ON SAFETY & HEALTH https://www.facebook.com/notes/ashe-institute/list-of-indian-standards-on-safety-health/1454504327997502/ NEBOSH IGC @ ASHEI KOCHI TUTOR : ANILKUMAR TS MENON CMIOSH FIIRSM OCTOBER BATCH REGISTRATION ONGOING…. CLASS STARTING ON: 9 – 19TH ...

EMS Auditor – ISO 14001:2015 Training Course @ ASHEI Kochi 8606108000 www.asheinstitute.com IRCA Certified EMS Auditor / Lead Auditor – ISO 14001:2015 Training Course EMS Auditor- IRCA is the leading professional body for management system auditors and offers a globally recognized business qua...

International Safety course in kochi!!! Health And Safety Auditing In Ernakulam / Cochin ISO 45001: 2018 IRCA Approved LA Training Course @ ASHEI Kochi Training By ANILKUMAR TS MENON We conduct batches every month for ISO 45001:2018 LA, EMS- ISO 14001:2015 LA, ISO 45001:2018- Migration cou...

Accident Investigation WHAT IS IT? Accident investigation is the process of determining the root causes of accidents, on-the-job injuries, property damage, and close calls in order to prevent them from occurring again. WHY IS IT IMPORTANT? Accident investigation will lead you to the real cause of wh...

Command word & Definition Command words are important to note while writing the examination. Identify – To give reference to an item, which could be its name or title. NB: normally a word or phrase will be sufficient, provided the reference is clear. Give – To provide short, fact...

NEBOSH Health and Safety at Work Qualification Health and Safety at Work Qualification A perfect introduction to health and safety. This introductory qualification will help improve the safety culture in your organisation, by equipping your workforce to identify and deal with hazards at work helping...

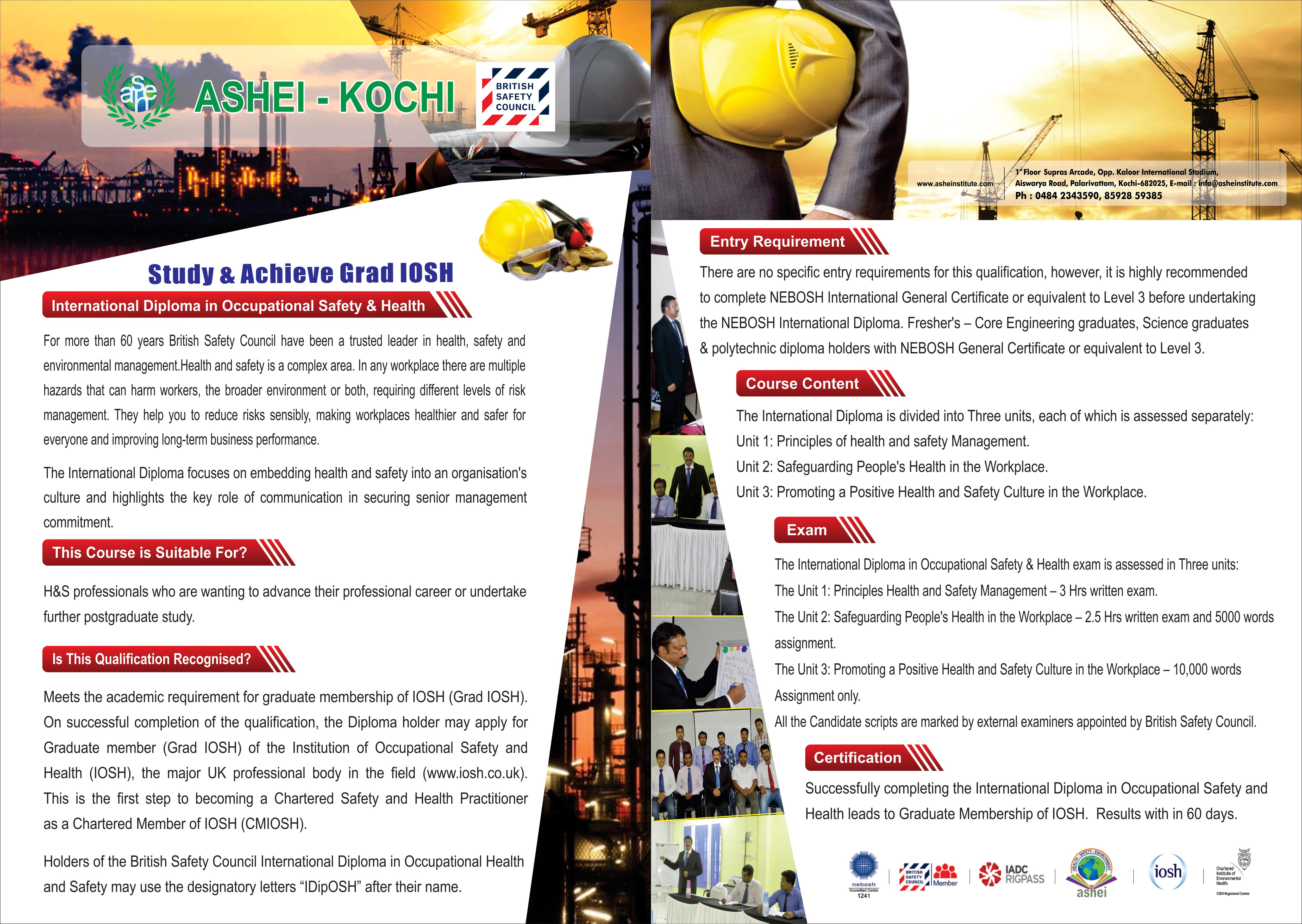

International Diploma in Occupational Safety & Health ASHE Institute, Kochi Proudly announce IDIPOSH certification for OHS professionals British Safety Council have been a trusted leader in health, safety and environmental management. They have educated millions of workers and made hundreds of...

TBT – TWO WHEEL HAND TRUCK TOOL BOX TALKS TBT Two-Wheel Hand Trucks PERSONAL PROTECTIVE EQUIPMENT Gloves that increase ability to grip cases. Footwear with protective toe and mid sole. BEST PRACTICES For large quantity loads provide a four-wheel platform-style cart or a two-whe...

Maintenance Shop Safety Maintenance Shop Safety Rules Employees must wear their seat belts when driving on company business. Report to work free from the aftereffects of drugs or alcohol. Horseplay is not permitted. Report maintenance needs or hazards before the end of your work shif...

WhatsApp us

WhatsApp us